|

|

SLT(System Level Test)

Utilize test equipment and classification machines to ensure that products operate stably under various scenarios through integrated testing and performance evaluation. This testing includes communication protocol, reliability and adaptability testing to ensure that the system meets actual application requirements. SLT not only tests hardware performance, but also examines the synergy between software and hardware. Effective SLT helps improve production efficiency, quality, reduce the risk of failure, and ensure the reliability and competitiveness of semiconductor products in the market. |

|

Burn In Services

A testing method for operating semiconductor components under high temperature and high voltage conditions for long periods of time, aiming to detect potential failures in advance and improve component reliability. Through Burn-In, the exposure of potential defects can be accelerated and the risk of early failure can be reduced. This test helps stabilize component performance, promotes the elimination of defective components, and improves overall production quality. Burn-In also helps ensure that semiconductor components are not affected by excessive stress during long-term use, improving their reliability and lifespan in practical applications. |

|

|

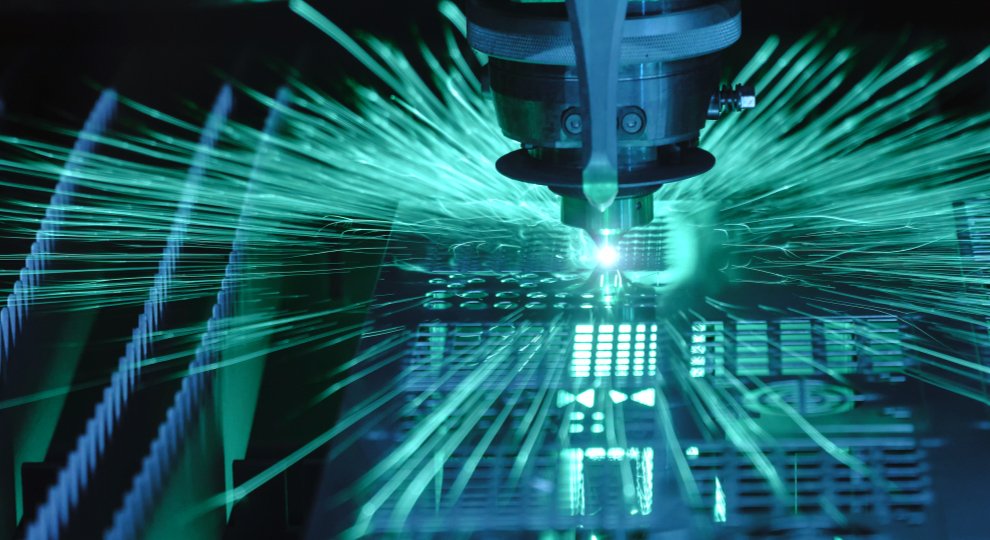

Laser Repair

The application of laser cutting and patching technology mainly uses precise laser beams to cut fused wires made of metal or polycrystalline silicon in integrated circuits to achieve the purpose of changing digital or analog circuits. |