Sigurd is committed to building a smart manufacturing system to make production more systematic, standardized, automated, predictable and transparent, giving customers peace of mind and confidence in entrusting outsourcing work to Sigurd.

Customers Products Application

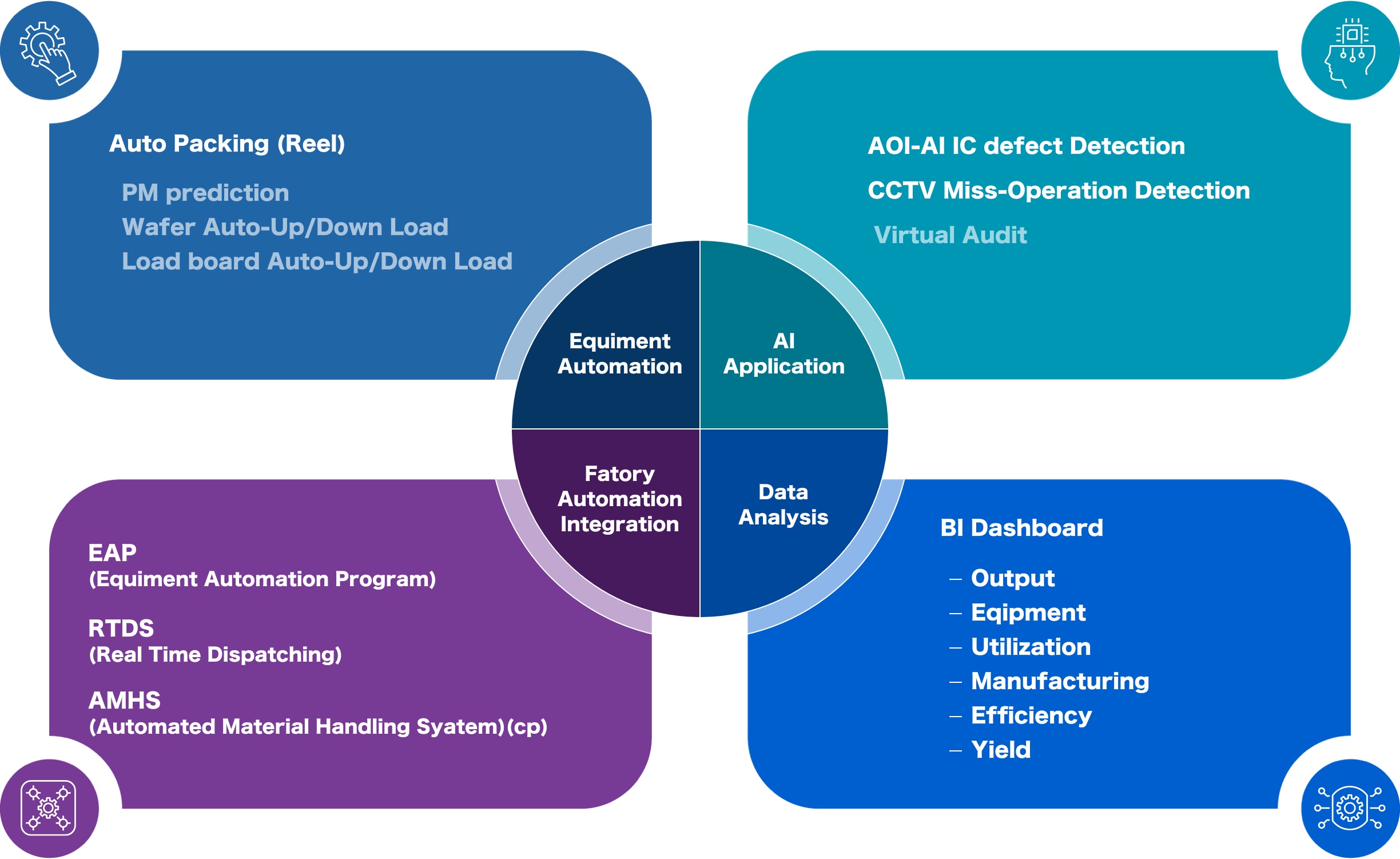

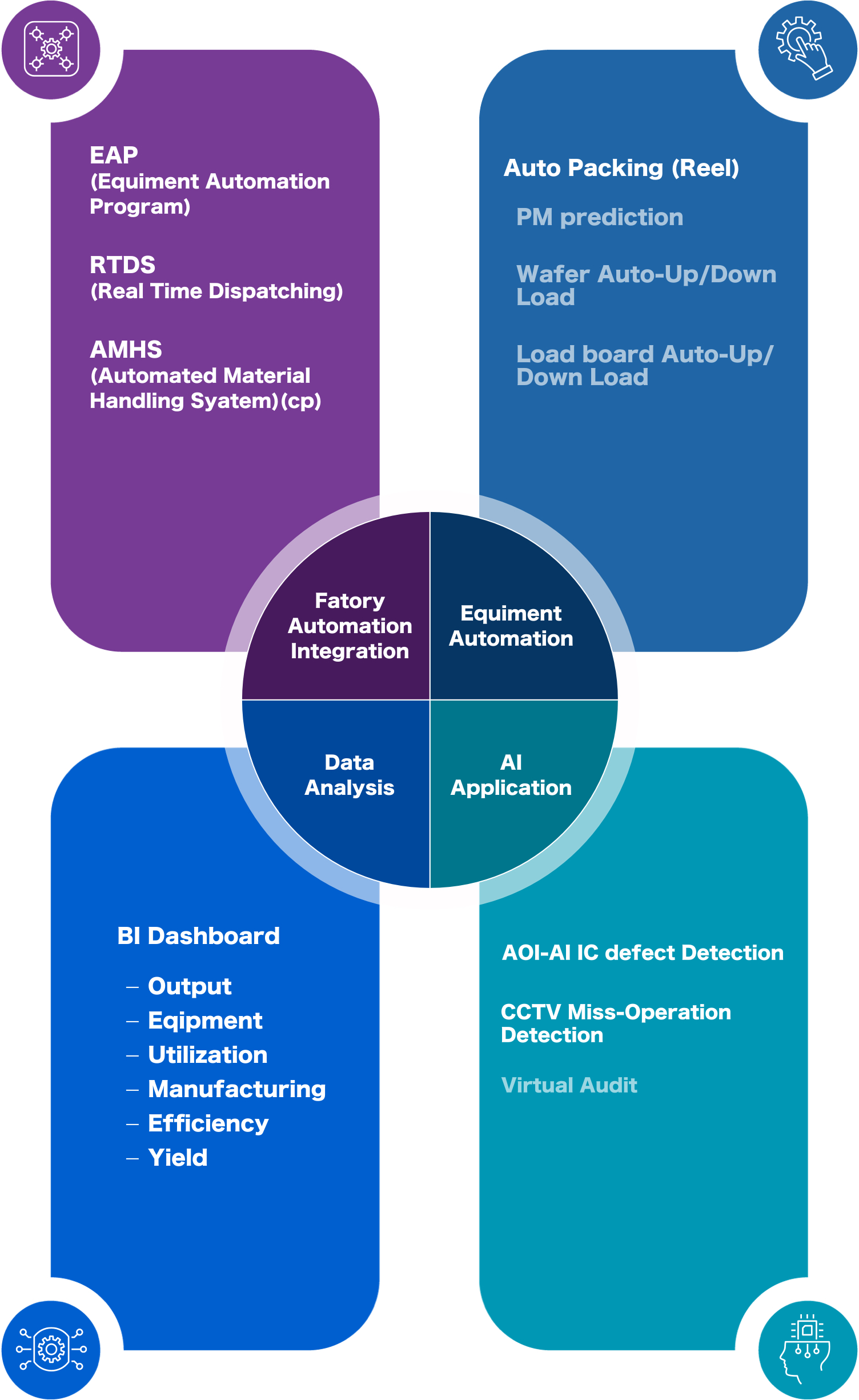

Artificial Intelligence

Sigurd has been actively applying artificial intelligence technology to our test production lines for a long time. Through machine learning and predictive analysis, AI can help us to explore the field that were previously inaccessible in daily operation.

Big Data Analysis

During the wafer packaging and testing process, a large amount of production data and information are generated and collected. Through data analysis technology, customers and companies can extract valuable information and insights from these data, which can be used to optimize production efficiency and quality control, and enhance customer competitiveness.

Factory Automation Integration

Automation integration can realize automated control and monitoring of production processes, thereby improving production efficiency and quality consistency. For example, automated equipment can realize automatic testing and inspection during the wafer packaging and testing process, reducing human intervention and errors.

Equipment Automation

Through equipment automation, intelligent control and automated operation of production equipment can be realized, thereby improving production efficiency and quality levels.